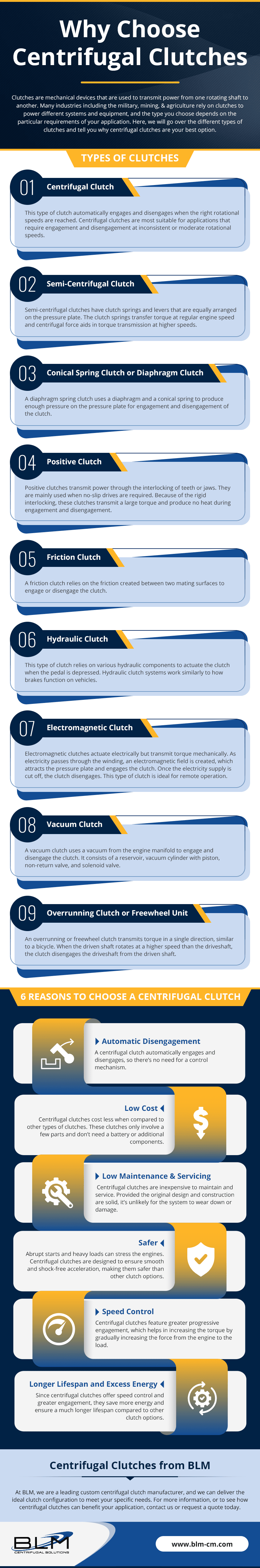

Clutches are mechanical devices that are used to transmit power from one rotating shaft to another. Many industries including, the military, mining, & agriculture rely on clutches to power different systems and equipment, and the type you choose depends on the particular requirements of your application. Here, we will go over the different types of clutches and tell you why centrifugal clutches are your best option.

Types of Clutches

There are nine main clutch types, including:

Centrifugal Clutch

This type of clutch automatically engages and disengages when the right rotational speeds are reached. Centrifugal clutches are most suitable for applications that require engagement and disengagement at inconsistent or moderate rotational speeds.

Semi-Centrifugal Clutch

Semi-centrifugal clutches have clutch springs and levers that are equally arranged on the pressure plate. The clutch springs transfer torque at regular engine speed and centrifugal force aids in torque transmission at higher speeds.

Conical Spring Clutch or Diaphragm Clutch

A diaphragm spring clutch uses a diaphragm and a conical spring to produce enough pressure on the pressure plate for engagement and disengagement of the clutch.

Positive Clutch

Positive clutches transmit power through the interlocking of teeth or jaws. They are mainly used when no-slip drives are required. Because of the rigid interlocking, these clutches transmit a large torque and produce no heat during engagement and disengagement.

Friction Clutch

A friction clutch relies on the friction created between two mating surfaces to engage or disengage the clutch.

Hydraulic Clutch

This type of clutch relies on various hydraulic components to actuate the clutch when the pedal is depressed. Hydraulic clutch systems work similarly to how brakes function on vehicles.

Electromagnetic Clutch

Electromagnetic clutches actuate electrically but transmit torque mechanically. As electricity passes through the winding, an electromagnetic field is created, which attracts the pressure plate and engages the clutch. Once the electricity supply is cut off, the clutch disengages. This type of clutch is ideal for remote operation.

Vacuum Clutch

A vacuum clutch uses a vacuum from the engine manifold to engage and disengage the clutch. It consists of a reservoir, vacuum cylinder with piston, non-return valve, and solenoid valve.

Overrunning Clutch or Freewheel Unit

An overrunning or freewheel clutch transmits torque in a single direction, similar to a bicycle. When the driven shaft rotates at a higher speed than the driveshaft, the clutch disengages the driveshaft from the driven shaft.

6 Reasons to Choose a Centrifugal Clutch

Here are some reasons why you should consider a centrifugal clutch over other types of clutches:

1. Automatic Disengagement

A centrifugal clutch automatically engages and disengages, so there’s no need for a control mechanism.

2. Low Cost

Centrifugal clutches cost less when compared to other types of clutches. These clutches only involve a few parts and don’t need a battery or additional components.

3. Low Maintenance & Servicing

Centrifugal clutches are inexpensive to maintain and service. Provided the original design and construction are solid, it’s unlikely for the system to wear down or damage.

4. Safer

Abrupt starts and heavy loads can stress the engines. Centrifugal clutches are designed to ensure smooth and shock-free acceleration, making them safer than other clutch options.

5. Speed Control

Centrifugal clutches feature greater progressive engagement, which helps in increasing the torque by gradually increasing the force from the engine to the load.

6. Longer Lifespan and Excess Energy

Since centrifugal clutches offer speed control and greater engagement, they save more energy and ensure a much longer lifespan compared to other clutch options.

Centrifugal Clutches from BLM

Although there is a wide range of clutch types to choose from, centrifugal clutches offer numerous advantages that make them a superior choice across several applications. At BLM, we are a leading custom centrifugal clutch manufacturer, and we can deliver the ideal clutch configuration to meet your specific needs. For more information, or to see how centrifugal clutches can benefit your application, contact us or request a quote today.

800.268.4295

800.268.4295