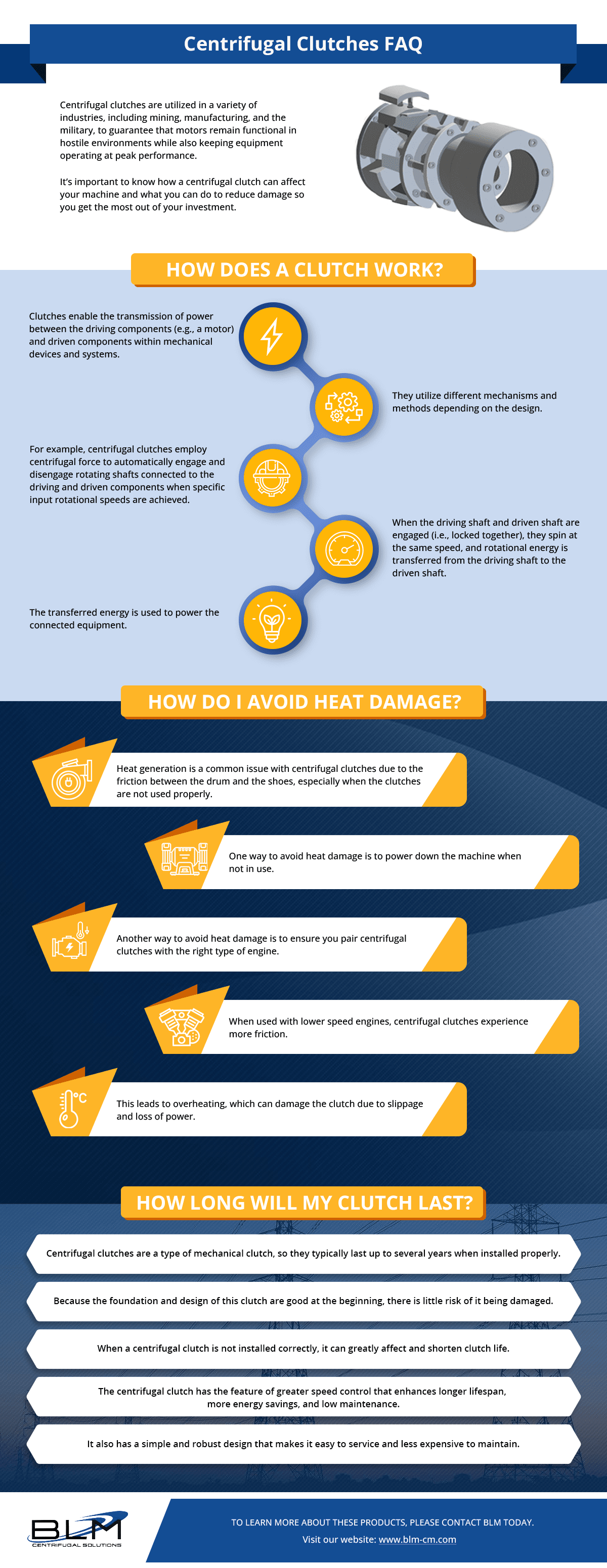

Answering Your Centrifugal Clutch Questions

Centrifugal clutches are utilized in a variety of industries, including mining, manufacturing, and the military, to guarantee that motors remain functional in hostile environments while also keeping equipment operating at peak performance.

It’s important to know how a centrifugal clutch can affect your machine and what you can do to reduce damage so you get the most out of your investment. That is why we’ve included answers to a few of the most frequently asked questions about our high quality clutches.

How does a clutch work?

Clutches enable the transmission of power between the driving components (e.g., a motor) and driven components within mechanical devices and systems. They utilize different mechanisms and methods depending on the design. For example, centrifugal clutches employ centrifugal force to automatically engage and disengage rotating shafts connected to the driving and driven components when specific input rotational speeds are achieved. When the driving shaft and driven shaft are engaged (i.e., locked together), they spin at the same speed, and rotational energy is transferred from the driving shaft to the driven shaft. The transferred energy is used to power the connected equipment.

How do I avoid heat damage?

Heat generation is a common issue with centrifugal clutches due to the friction between the drum and the shoes, especially when the clutches are not used properly. When too much heat is generated, it can cause permanent damage to the clutch. Heat damage also causes the clutch to not disengage, causing the machine to accelerate by itself as soon as the engine turns on.

To avoid heat damage, centrifugal clutches need to be properly maintained. One way to avoid heat damage is to power down the machine when not in use. Disregarding these tips can lead to permanent heat damage, which may completely destroy the clutch, resulting in costly replacements.

Another way to avoid heat damage is to ensure you pair centrifugal clutches with the right type of engine. Centrifugal clutches are ideal for high speed engines rather than lower speed engines. When used with lower speed engines, centrifugal clutches experience more friction. This leads to overheating, which can damage the clutch due to slippage and loss of power.

How long will my clutch last?

Centrifugal clutches are a type of mechanical clutch, so they typically last up to several years when installed properly. Because the foundation and design of this clutch are good at the beginning, there is little risk of it being damaged. When a centrifugal clutch is not installed correctly, it can greatly affect and shorten clutch life.

The centrifugal clutch has the feature of greater speed control that enhances longer lifespan, higher energy accumulation on startup, and low maintenance. It also has a simple and robust design that makes it easy to service and less expensive to maintain.

Does BLM do Automotive or Car Applications for clutches?

BLM does not manufacture clutches for automotive or car applications. We provide industrial equipment solutions in a wide range of industries, including agriculture, mining, waterworks, and more!

BLM is committed to providing innovative solutions for centrifugal clutch applications across industries, so if you have questions about centrifugal clutches or need help finding the right solution for your industry, request a FREE quote or contact us today!

800.268.4295

800.268.4295