At BLM Automatic Clutch Centrifugal Solutions, we have been providing our customers with custom centrifugal clutches for over 80 years. Regardless of application, our experienced team can provide the correct clutch configuration to meet your specific requirement. We offer various coupling, flywheel, universal shaft, pulley, and soft start combinations.

Coupling combination options include close shaft mounting, gap mounting, and gear coupling configurations. Flywheel mounting options include directly coupling, Type FMU for use with universal shafts, and flexible element arrangement which is particularly useful when dealing with torsional vibration issues. Universal shaft combinations include Type E for use with a Spicer shaft in heavy duty applications, or Type HMU universal joint. Multiple pulley styles including integral sheave, timing pulleys, step pulleys, single pulleys, double pulleys, and flywheel mounted pulley can be utilized, depending on the design requirements of the equipment. Soft start combinations include the double “C” flange designed for use between the motor and reducer, or its metric counterpart, the “D” flange.

Clutches can be designed to work with either gas or electric motors from 1 to 3,000 horse power and can vary from 3 to 30 inches in diameter. Finished products can be either painted or plated per customer’s specifications. Our centrifugal clutches can be found in pumps, mortar mixers, augers, power trowels, compressors, saws, kilns, and more. We offer maintenance, repair, and warranties on all of our products. For more information about our custom centrifugal clutches, see the table below, or contact us directly.

Centrifugal clutches transfer rotational power from the power source (e.g., an engine, motor, or turbine) to the intended load for acceleration. These devices employ centrifugal force to safely transfer energy from the power source’s shaft to the drive shaft or transmission without stalling or causing damage to the mechanical equipment.

BLM Automatic Clutch produces custom centrifugal clutches designed to power industrial equipment. With 87 years of designing and manufacturing high quality clutches for industrial, military, public, and chemical applications, we have the knowledge and expertise to provide the optimal clutch for your equipment.

Custom Centrifugal Clutches vs. Manual, Hydraulic, and Electrical

There are many types of clutches available to connect prime movers, such as motors and engines, to loads and equipment. They can be designed and constructed to have various sizes, construction materials, or special features, as well as employ different mechanisms to connect to a load or a piece of equipment. These differences enable centrifugal clutches to provide certain advantages over other types of clutches, including manual, hydraulic, and electric clutches.

How a Centrifugal Clutch Operates: Read the Blog

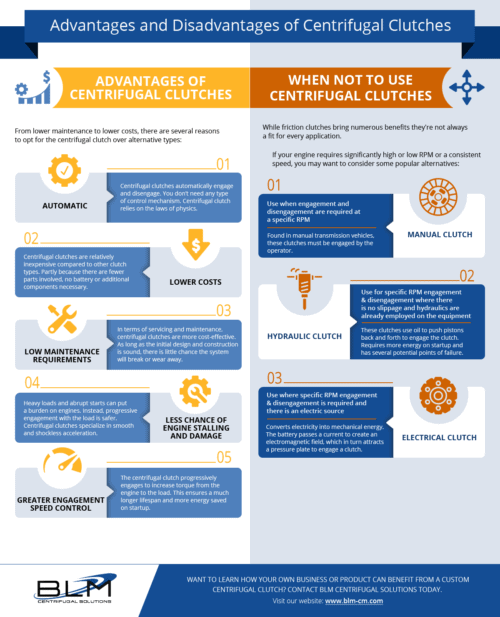

Advantages of Centrifugal Clutches

There are quite a few advantages of centrifugal clutches, especially for extending the life of the connecting equipment.

Centrifugal clutches are simple parts that can be easily installed, monitored, and replaced as needed. The parts are also available in customized design, so the complexity of any system can be handled without the need for additional parts or mechanisms. Centrifugal clutches are commonly used by small-motor industries because they offer a wide range of benefits, including:

- Low maintenance requirements. The simplicity of the centrifugal clutch design facilitates servicing and maintenance operations. Once the part design has been tested to ensure a proper fit for the engine’s power and the load’s force requirements, it can perform with little wear or breakage.

- Automatic operation. The clutch mechanism operates automatically without the need for manual operator control, which saves time in preventing engine stall or damage.

- Automatic engagement and disengagement. Centrifugal clutches do not need separately powered and fallible systems.

- Lower costs. As these clutches use the centrifugal forces that are already generated by the prime mover, facilities do not need to invest in additional power sources or components. Centrifugal clutch components themselves are also low cost once the design is prototyped and finalized.

- Greater engagement speed control. Smooth engagement is an important part of extending any machinery’s lifespan. To smooth the delivery of power, clutches progressively engage to gradually increase the torque from the engine to the load or transmission.

- Reduced risk of engine stalling and engine damage. Sudden starts, heavy loads, and overloading put unnecessary stress on engines and motors. They perform better when they can progressively engage with heavy equipment. Centrifugal clutches provide this buffer from shock and immediate overload by allowing the motor to get to a controlled point of operation before connecting to the load.

- Smoother acceleration operations. These clutches can provide smoother acceleration with less shock.

- Starting capabilities without load. These clutches enable prime movers to operate without an initial load.

- No requirement for expensive starting equipment. Other clutches require safety guards or additional equipment to protect the motor and fragile parts during startup, but centrifugal clutches do not engage with the transmission until sufficiently powered.

- Automatic slippage to protect the engine. Overloads can make engines stall and put a lot of wear on the parts over time. Centrifugal clutches slip automatically without manual overrides and disengagements that other clutches often require.

- Potential use with small motors. Because the motor does not immediately have to generate enough power to engage with the transmission or load, it can be smaller. The motor can power up through progressive stages, contributing to their lower startup energy cost.

View Our Catalog of Custom Centrifugal Clutches CAD Drawings

Centrifugal Clutches vs. Manual Clutches

Manual clutches are commonly found in manual transmission passenger and industrial vehicles. These clutches rely on the operator to engage the clutch, act to prevent problems and slippage, and maintain awareness of wear on the clutch and motor.

Manual clutch systems may include two different components of operation that centrifugal clutches do not need:

- Dog and spline clutches: These systems lock together and are susceptible to grinding and breakage along the teeth. They also require manual control to engage and disengage. While not every manual clutch is a dog and spline clutch, they are the most common type.

- Clutch pedal: Clutch pedals are manual pedals that are pressed and released to engage and disengage the shaft to the driving mechanism of the load or transmission.

Centrifugal Clutches vs. Hydraulic Clutches

Hydraulic clutches use pressurized oil to move pistons back and forth to engage or disengage the clutch. A pump powered by the prime mover releases oil from a reservoir to an accumulator and a control valve. The control valve allows the fluid to engage the pistons or return to the reservoir as needed.

Compared to centrifugal clutches, these clutches require more energy on startup and have multiple points of potential failure. They also require constant maintenance to prevent leaks and fluid loss.

Centrifugal Clutches vs. Electrical Clutches

Electrical and electromagnetic clutches use an electrical power source that converts electricity into mechanical energy to transmit torque. A battery passes an electric current through windings to produce an electromagnetic field. This field attracts a pressure plate, moving it to engage the clutch. To disengage the clutch, the battery shutoffs to dissipate the electromagnetic field.

The energy used to activate this clutch turns into heat, which can quickly overheat an engine. Although some electromagnets are insulated, reducing the risk of overheating, it also limits the amount of torque the field can provide. Centrifugal clutches, on the other hand, are designed to prevent overheating and do not have this design limitation.

Finding Centrifugal Solutions

Centrifugal clutches play a critical role in driving torque and protecting prime mover equipment and systems across a wide range of industries.

At BLM Automatic Clutch, we have been a custom centrifugal clutch manufacturer for over 85 years with capabilities for designing, modifying, and constructing centrifugal clutches with short lead times. We also have experience with public and military contracts to create specialized centrifugal clutches that work in extreme conditions. Specifically, we have a long history of manufacturing custom centrifugal clutches for the:

- Agriculture/Forestry industry

- Chemical industry

- City waterworks industry

- Military defense industry

- Mining industry

- Public works industry

Our custom centrifugal clutches are ISO 9000 compliant and available in prototype, small, and large runs with options for painted or electroplated finishes based on customer request. We also offer maintenance and repair services and warranties for all products we manufacture. With just two to three weeks of lead time, we can supply centrifugal clutches that are tailored to the specific requirements of your application.

Request a Quote from BLM Automatic Clutch

Centrifugal clutches are simple, safe solutions for providing torque and power from an engine or motor to a transmission and load. As a custom centrifugal clutch supplier, BLM Automatic Clutch designs and customizes services unmatched by any other clutch manufacturer. We stand by the quality and longevity of our centrifugal clutches with long term manufacturer support and warranties.

Contact us today with the details of your project to receive a quote.

Custom Centrifugal Clutch Highlights

Project Name

Centrifugal Clutches

Combinations

Coupling

Flywheel

Universal Shaft

Pulley

Soft Start

Custom Designs

Coupling Combinations Shaft to Shaft In-Line Mounting

Close Shaft Mounting (Type A)

Gap Mounting (Type B)

Gear Coupling (Type GMG)

Flywheel Combinations Engine Flywheel Mount

Direct Coupling (Type C)

Universal Shafts (Type FMU)

Flexible Element (Type PMH)

Universal Shaft Combinations Engine (or Motor) Shaft Mount

Integral Sheave (Type F)

Timing Pulleys

Step Pulleys

Single Pulleys

Double Pulleys

Flywheel Mounted

Soft Start Combinations

Double “C” Flange

Metric “D” Flange

Power Source

Electric Motor

Gas / Diesel Engine

Power

1 to 3,000 HP

Rotational Speed

600 to 3600 RPM

Idle Speed

800 to 2,000 RPM

Materials

Cast Iron

Ductile Iron

Steel

Finish

Paint

Electroplating

Diameter

3 to 30 in

Weight

Up to 1,000 lbs.

Inspection

Dimensional

Additional Services

Repair

Maintenance

Warranty

Production Volume

Prototype

Small Runs

Large Runs

Typical Lead Time

2 to 3 weeks

Additional Information

Industry Focus

Agricultural

Commercial

Construction Rental

Industrial

Mining

Pulp and Paper

Intended Applications

Brake Drums

Centrifuges

Chippers

Compressors

Concrete Pumps

Conveyors

Crushers

Curbers

Deep Well Pumps

Diesels

Earth Augers

Fans

Industrial Sweepers

Mixers

Mortar Mixers

Pumps

Rotary Kilns

Sand

Saws

Swedges

Tampers

Textile Machinery

Trowels

Truck Refrigeration

Industry Standards

ISO Compliant

Canadian Federation of Independent Business (CFIB)

800.268.4295

800.268.4295