Centrifugal clutches provide several distinct advantages over alternative clutch designs, including:

Centrifugal Clutches: A Selection Guide

A centrifugal clutch is a mechanical device that uses centrifugal force to convey movement in driven rotary equipment. Primarily used with a combustion engine or electric motor, the clutch operates as a soft start device that enables the engine to start on idle with no load engagement. By engaging only when a designated rotational speed is exceeded, centrifugal clutches allow engines to reach their optimal torque before carrying the load.

A centrifugal clutch is a mechanical device that uses centrifugal force to convey movement in driven rotary equipment. Primarily used with a combustion engine or electric motor, the clutch operates as a soft start device that enables the engine to start on idle with no load engagement. By engaging only when a designated rotational speed is exceeded, centrifugal clutches allow engines to reach their optimal torque before carrying the load.

Advantages of Centrifugal Clutches/Friction Clutches

- Automatic engagement / disengagement. Centrifugal clutches are designed to automatically engage or disengage according to the engine's rotational speed. This eliminates the need for external control mechanisms.

- Low cost. With fewer components required to support their operation, centrifugal clutches are one of the most cost-effective clutch options available. The wearing parts of the clutch are also inexpensive and easy to replace.

- Low maintenance. When designed and constructed properly, centrifugal clutches have much lower maintenance and servicing requirements compared with alternative clutch types.

- Less susceptible to stalling and engine damage. By gradually engaging the load to the engine, centrifugal clutches reduce the risk of abrupt starting or overloading. Benefits of this include smooth and shock-free acceleration, less stalling, safer operation, and longer engine lifespan.

- Better speed control. With centrifugal clutches, the engaging speed can be precisely controlled through spring selection.

Parts in a Centrifugal Clutch

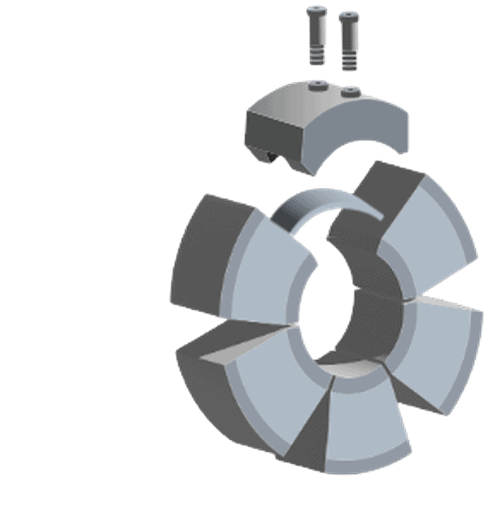

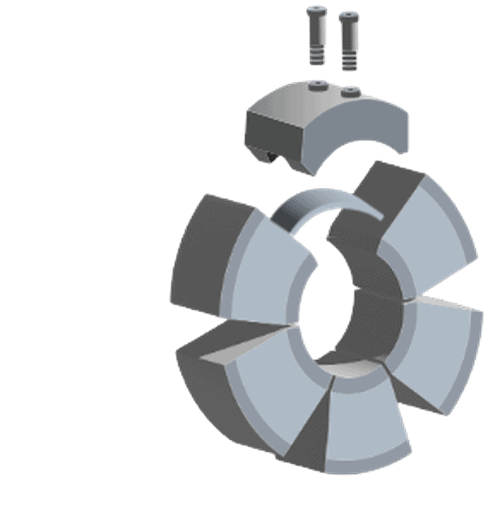

Centrifugal clutches are comprised of several interacting components, each of which provides a specific function. These include:

Parts in a Centrifugal Clutch

Centrifugal clutches are comprised of several interacting components, each of which provides a specific function. These include:

-

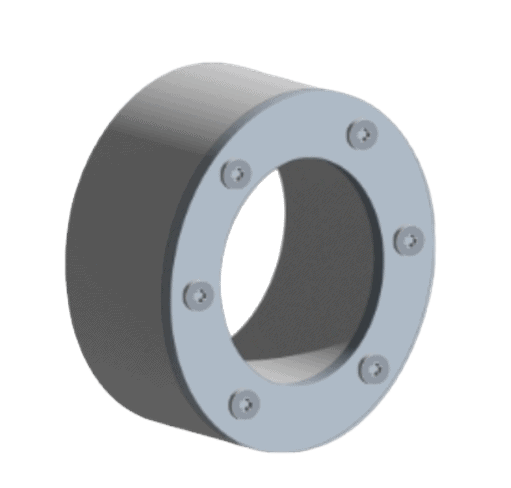

Drum / housing

Mounted to the driven shaft of the transmission system, the drum houses the guides, sliding shoes, springs, and other internal components of the centrifugal clutch.

-

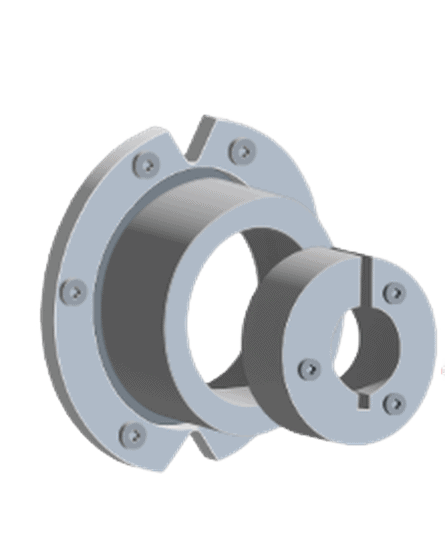

Hub

The hub, which is connected to the motor or driving shaft, is the rotating centerpiece of the clutch. The rotation of the hub forces the clutch’s shoes outward until they encounter the drum.

-

Springs

Centrifugal clutches rely on tension clutch springs, which are extension springs with specialized hooks at each end. The springs connect the shoes to the guide and act as a control element. Their primary function is to hold the shoes securely in position until the rotational speed designated for engagement is reached. A weaker spring paired with a heavier shoe allows the clutch to engage at a lower rotational speed, while a stronger spring paired with a lighter shoe enables engagement at a higher rotational speed.

-

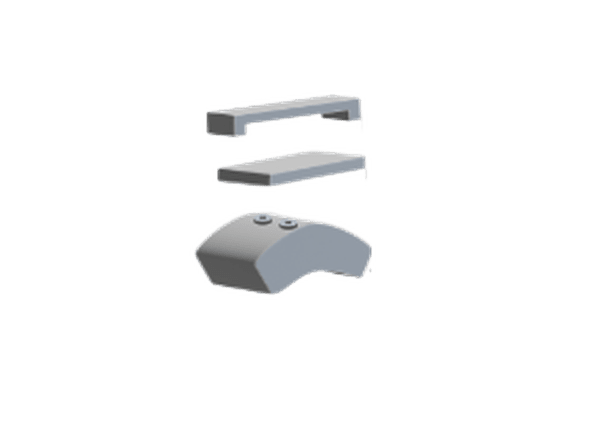

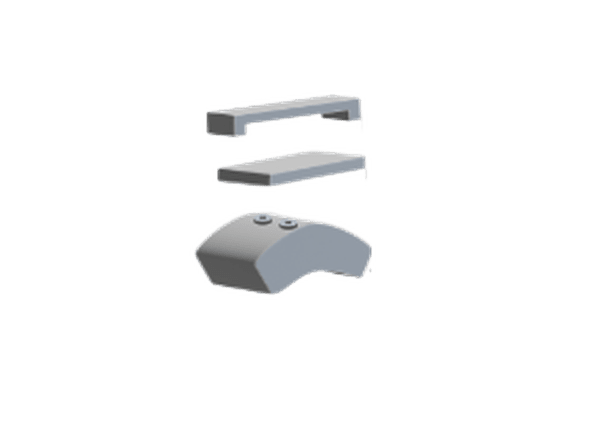

Clutch shoes / flyweights

The clutch’s shoes, also known as flyweights, push outward against the drum during engagement. When the clutch is idle, the springs connected to each shoe contract to prevent torque transfer.

-

Linings

Friction linings are attached to the outer ends of each shoe to provide a good grip and prevent slippage when the shoes make contact with the drum’s surface. These linings are usually made of rough, high friction materials containing metallic particles.

How Does a Centrifugal Clutch Work?

The centrifugal force, which is generated by the engine’s revolutions, is transmitted using two or more clutch shoes. In most engines, the centrifugal clutch is mounted to the engine’s crankshaft, and the clutch shaft rotates at a speed that is equal to that of the engine. The speed at which the clutch engages is influenced by the springs, shoes, and friction lining.

Automatic clutch engagement or disengagement occurs through the following processes:

- Engagement. As the engine’s speed increases, the centrifugal force increases and exceeds the force of the springs. This forces the shoes outward toward the drum. When the designated rotational speed for engagement is reached, the clutch automatically engages by pressing the shoes against the drum’s inner surface. The friction lining then allows the torque to be transmitted from the shoes to the drum.

- Disengagement. When the engine slows down, the centrifugal force decreases. This causes the springs to contract, pulling the shoes back to their initial position and disengaging the clutch.

Common Applications for a Centrifugal Clutch

Centrifugal clutches are ideal for equipment requiring automatic engagement or disengagement at moderate or variable speeds. Specific applications include:

Street sweepers

In street sweeping equipment, centrifugal clutches form a mechanical connection between the power source (engine, motor, etc.) and the load requiring acceleration.

Wood chippers

Centrifugal clutches provide automatic engagement and disengagement in wood chipping equipment used for cutting tree branches and trunks into smaller wood chips.

Motor pumps

When used in motor pumps, centrifugal clutches allow the engine to warm up by only engaging when a specific RPM is reached or exceeded.

Grounds maintenance

Centrifugal clutches are often used in grounds maintenance equipment such as trimmers and lawnmowers. The clutch automatically engages as the equipment’s engine accelerates in speed and disengages when the engine begins to throttle down.

Centrifugal Clutches from BLM

Centrifugal clutches provide a safe and reliable power transmission solution for equipment requiring load-free starting and smooth, shock-free acceleration. BLM designs and manufactures custom centrifugal clutches for a variety of applications, from compact road and street sweepers to compressor, vacuum, and fan drives. Our specific clutch capabilities include:

- Prototype development. Our in-house design and engineering team works with customers to transform their clutch concepts into functional prototypes that can be validated under relevant conditions. Everything from the clutch’s design to its construction materials can be tested and fine-tuned for optimization prior to actual production.

- One-off production. Our flexible, customer-oriented manufacturing approach allows us to provide high-quality one-off clutch solutions for a range of unique or challenging power transmission applications.

- CNC machining. Using a range of state-of-the-art CNC machining equipment, our experienced machinists produce high-precision clutches that are optimized to meet various horsepower, RPM, and operational requirements.

To learn more about our clutch solutions and how they can be customized for your application, please contact us, request a quote, or visit our Capabilities page.

800.268.4295

800.268.4295

Comments are closed