Category Archive: Uncategorized

Frictional Clutches 101: Benefits & Applications

A clutch controls a machine’s power transmission or motion. Clutches can control these factors on-demand or over time. Frictional clutches transmit power by harnessing friction between two contacting surfaces. This mechanism offers specific benefits over other types of clutches. We will discuss these advantages, as well as the features and types of frictional clutches that fit certain applications.

Advantages of Frictional Clutches

Frictional clutches are one of the most popular types of clutches and for good reason. They are easy to operate, especially in situations that require frequent engagement and disengagement while the machine is running. This is possible because frictional clutches have no teeth, which smooths engagement and reduces shock.

Frictional clutches can also transmit partial power and act as a safety mechanism. For example, when torque exceeds a certain level, the frictional clutch slips and protects the machine from overloading.

Features of Frictional Clutches

These are the main types of frictional clutches:

- Centrifugal: These clutches are used in machines where the engine speed defines the clutch’s operation. An example is a chainsaw, which utilizes centrifugal force to engage the clutch if the engine’s RPM goes over a specific threshold. The clutch disengages automatically when the engine’s RPM falls below the limit.

- Cone clutch: A cone clutch is made up of a pair of male and female conical friction surfaces. The cone clutch can transfer a higher amount of torque than disk clutches because the conical taper slows the approach of the friction surfaces. This translates into more pressure and friction between the mating surfaces.

- Torque limiter: A torque limiter is also called a slip clutch or safety clutch because it slips if the machine encounters resistance that is higher than normal. A good example of this device is the clutch on lawnmowers. If the mower hits a rock or immovable object, the clutch yields and prevents the equipment from damaging itself.

Frictional Clutches From BLM

Founded in 1932, BLM Automatic Clutch has been designing and producing custom clutches for our clients. Our two main product lines are Four Block Series clutches—for chippers, concrete pumps, conveyors, refrigerators, and more—and Six Block Series clutches for large industrial and commercial machinery. These are all centrifugal clutches fit for a variety of municipal, chemical, military, and other critical applications.

Contact us for more information about our frictional clutches, or request a quote to learn how we can help with your project.

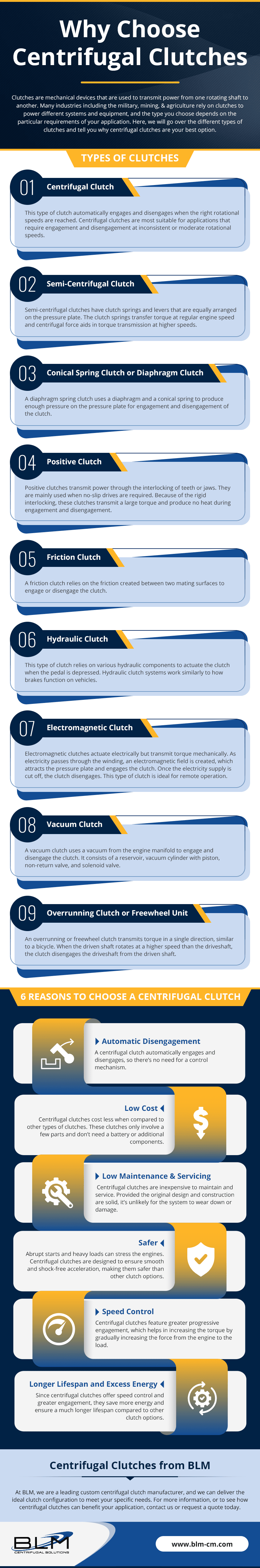

Why Choose Centrifugal Clutches Over Other Clutch Types

Clutches are mechanical devices that are used to transmit power from one rotating shaft to another. Many industries including, the military, mining, & agriculture rely on clutches to power different systems and equipment, and the type you choose depends on the particular requirements of your application. Here, we will go over the different types of clutches and tell you why centrifugal clutches are your best option.

Types of Clutches

There are nine main clutch types, including:

Centrifugal Clutch

This type of clutch automatically engages and disengages when the right rotational speeds are reached. Centrifugal clutches are most suitable for applications that require engagement and disengagement at inconsistent or moderate rotational speeds.

Semi-Centrifugal Clutch

Semi-centrifugal clutches have clutch springs and levers that are equally arranged on the pressure plate. The clutch springs transfer torque at regular engine speed and centrifugal force aids in torque transmission at higher speeds.

Conical Spring Clutch or Diaphragm Clutch

A diaphragm spring clutch uses a diaphragm and a conical spring to produce enough pressure on the pressure plate for engagement and disengagement of the clutch.

Positive Clutch

Positive clutches transmit power through the interlocking of teeth or jaws. They are mainly used when no-slip drives are required. Because of the rigid interlocking, these clutches transmit a large torque and produce no heat during engagement and disengagement.

Friction Clutch

A friction clutch relies on the friction created between two mating surfaces to engage or disengage the clutch.

Hydraulic Clutch

This type of clutch relies on various hydraulic components to actuate the clutch when the pedal is depressed. Hydraulic clutch systems work similarly to how brakes function on vehicles.

Electromagnetic Clutch

Electromagnetic clutches actuate electrically but transmit torque mechanically. As electricity passes through the winding, an electromagnetic field is created, which attracts the pressure plate and engages the clutch. Once the electricity supply is cut off, the clutch disengages. This type of clutch is ideal for remote operation.

Vacuum Clutch

A vacuum clutch uses a vacuum from the engine manifold to engage and disengage the clutch. It consists of a reservoir, vacuum cylinder with piston, non-return valve, and solenoid valve.

Overrunning Clutch or Freewheel Unit

An overrunning or freewheel clutch transmits torque in a single direction, similar to a bicycle. When the driven shaft rotates at a higher speed than the driveshaft, the clutch disengages the driveshaft from the driven shaft.

6 Reasons to Choose a Centrifugal Clutch

Here are some reasons why you should consider a centrifugal clutch over other types of clutches:

1. Automatic Disengagement

A centrifugal clutch automatically engages and disengages, so there’s no need for a control mechanism.

2. Low Cost

Centrifugal clutches cost less when compared to other types of clutches. These clutches only involve a few parts and don’t need a battery or additional components.

3. Low Maintenance & Servicing

Centrifugal clutches are inexpensive to maintain and service. Provided the original design and construction are solid, it’s unlikely for the system to wear down or damage.

4. Safer

Abrupt starts and heavy loads can stress the engines. Centrifugal clutches are designed to ensure smooth and shock-free acceleration, making them safer than other clutch options.

5. Speed Control

Centrifugal clutches feature greater progressive engagement, which helps in increasing the torque by gradually increasing the force from the engine to the load.

6. Longer Lifespan and Excess Energy

Since centrifugal clutches offer speed control and greater engagement, they save more energy and ensure a much longer lifespan compared to other clutch options.

Centrifugal Clutches from BLM

Although there is a wide range of clutch types to choose from, centrifugal clutches offer numerous advantages that make them a superior choice across several applications. At BLM, we are a leading custom centrifugal clutch manufacturer, and we can deliver the ideal clutch configuration to meet your specific needs. For more information, or to see how centrifugal clutches can benefit your application, contact us or request a quote today.

Centrifugal Clutches – Common Problems & Solutions

Centrifugal clutches, or friction clutches, are used in a wide variety of machinery and engine applications. In comparison to other types of clutches, centrifugal clutches generally have lower maintenance requirements. A well-designed and maintained centrifugal clutch should provide a long and reliable service life.

Centrifugal Clutch Won’t Engage

If your clutch won’t engage, It usually means that the engine idle speed is different to the clutch idle speed. This can result in damage. To correct this, change the spring or change the engine speed to below the clutch idle speed. If damage is excessive it will require the repair or replacement of the clutch.

Slipping Centrifugal Clutch

If your clutch is slipping you may notice a burning lining smell. Due to the clutch slipping, overheating will occur. It’s important to assess situations like this as soon as possible as this leads to heat damage to the inside of the clutch drum. This may then require replacement of the mechanism because the clutch will no longer engage. Unfortunately, heat damage is not covered by a warranty.

Centrifugal Clutch Engages Early

A common reason for a clutch engaging early is due to the engine idle speed being too high. Another possibility is that the tension springs are too loose. This could occur due to excessive wear and will eventually cause the flyweights to prematurely engage.

There are different solutions to consider, depending on your exact problem. If your clutch is engaging early because your engine idle speed is set too high, you will need to reconfigure the engine by adjusting the engine idle speed. Depending on the extent of the damage, it might be necessary to replace the entire clutch.

Custom Centrifugal Clutch Solutions

If you’re experiencing issues with your centrifugal clutch, finding a solution is usually a quick process that might involve replacing a small internal component. In many cases, problems can be avoided by maintaining a proper maintenance schedule.

A high-quality centrifugal clutch should provide a long service life. BLM Automatic Clutch has been designing customized clutches for industrial and commercial applications for over 89 years. With applications ranging from military and defense to agriculture, city waterworks, and more, our products power the world. To begin developing your solution, contact us today.

The Importance of Centrifugal Clutches in Engines

Centrifugal clutches are integral to the operation of many mechanical devices and systems. By transmitting power between the driving components and the driven components, they enable machines to start and stop operations as needed. Below, we discuss how these devices work and what role they play with engines.

How Do Centrifugal Clutches Work?

All clutches stop and start the transmission of power by engaging and disengaging the driving shaft and the driven shaft. The exact power transmission method and mechanism depends on the type of clutch used. For instance, centrifugal clutches rely on centrifugal force to automatically engage and disengage the shafts.

The centrifugal clutch design consists of a drum attached to an output shaft, sheave, or sprocket that contains internal flyweights. As the power source revs, the driving shaft turns, which produces centrifugal force within the clutch. The force generated is relative to the input speed—lower speeds generate lower centrifugal force, while higher speeds generate higher centrifugal force. At a certain speed, the centrifugal speed is sufficient enough to force the flyweights to move outward, which makes them come into contact with the inside of the drum. This contact causes the drum to rotate and gradually engage the clutch. If the speed decreases below the engagement point, the flyweights retract, the drum rotation stops, and the clutch disengages.

What Role Do Centrifugal Clutches Play in Engines?

In engine-powered systems, centrifugal clutches are found between the engine flywheel and the transmission. They connect the engine driveshaft to the transmission shaft only once there is sufficient power. This protects the engine during startup/shutdown and prevents continuous operation when it is idled down.

Generally, centrifugal clutches are integrated into mobile equipment with high-speed rotational parts driven by small engines. Typical small engine applications for centrifugal clutches include:

- Groundskeeping and landscaping equipment, such as cutters and mowers

- Mining equipment, such as vibratory compactors, pumps, and rollers

- Wood processing equipment, such as grinders, mills, and woodchippers

While centrifugal clutches can be used in a wide range of applications, they are not appropriate for every application. For example, they are not suitable for applications involving the transfer of high torque or power since they exhibit a tendency to slip if the load is too heavy. Additionally, they are not suitable for applications requiring high-reliability disengagement.

Centrifugal Clutches for Engines from BLM

Centrifugal clutches are critical components of engine-powered machinery. When properly chosen for the given application, they can eliminate shock loading of the powertrain, enable smooth acceleration, and protect the motor and machine from overloading.

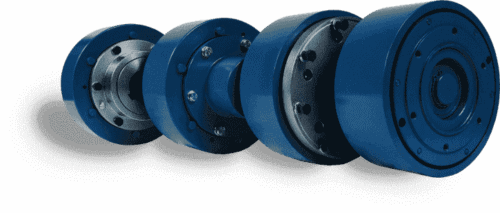

Need centrifugal clutches for your engine-based systems? The experts at BLM Automatic Clutch are here to help! Our Four Block Series clutches (1/4 to 50 hp) are suitable for small equipment (e.g., chippers, concrete pumps, conveyors, mortar mixers, refrigeration systems, and tampers), while our Six Block Series clutches (up to 3,000 hp) are suitable for large industrial and commercial equipment (e.g., brake drums, crushers, centrifuges, fans, pumps, and textile machinery). Additionally, our team can design and manufacture custom centrifugal clutches with fractional to 3,000 hp input speeds capacities.

All of our clutches are carefully engineered to allow for:

- Automatic engagement/disengagement

- Motor start without load

- Smooth acceleration without shock

- Use of smaller motors

- Slip in overload conditions

- Low-energy startup

- Simple and quick maintenance

To learn more about our standard and custom centrifugal clutch offerings, contact us today. To discuss your specific clutch requirements and restrictions with one of our experts, request a quote.

A Message to the BLM Community Amidst COVID-19

To our BLM Customers:

As we, at BLM, are monitoring the ever-changing climate of the COVID-19 pandemic, we want to assure you that our number one priority is the health and safety of our employees, customers and suppliers.

Supply Chain Impacts

We are constantly monitoring for any impact. We have assessed a very low risk to our supply chain and business capabilities. We have several plans in place that ensure having multiple resources for the quality materials necessary to complete your projects.

Our Commitment to Employees’ Safety

- No employees will be travelling at this time.

- Any employee who is sick will be asked to stay home until medical clearance is given

- Enhanced cleaning & sanitization plan for our facilities is now in place.

- Social distancing, no handshakes, and repeated hand washing and hand sanitizing is observed.

Visitors to our facility

As we continue to monitor this continuously changing situation, we are putting a hold on any non-essential visitors to our facility for at least 30 days, or until conditions and risk factors improve. We will rely on information provided by our Federal and Provincial leaders and the CDC to determine best courses of action going forward.

As always, please don’t hesitate to contact us if there’s anything we can assist with.

Sincerely,

Rob Wilson

President

The Waterworks Industry Prepares for the Future Where Keeping Water Pumping and Flowing Will Continue to be Critical

Each day, water utilities and other companies in the waterworks industry face challenges, some more critical than others. For example, the current California drought affects the waterworks industry and millions of people in the state, with repercussions in other industries and other states and locations around the world. The agriculture industry is affected, with limited irrigation abilities. Water conservation is being encouraged everywhere. Unfortunately, things don’t seem to be changing any time in the near future.

Last week, the U.S. Drought Monitor website, produced through a partnership between the National Drought Mitigation Center at the University of Nebraska-Lincoln, the U.S. Department of Agriculture and the National Oceanic and Atmospheric Administrations, reported, “The benefits of the February and early-March precipitation rapidly diminished across California and the Southwest as unseasonable warmth and dryness increased water demands and depleted snowpacks.” A recent report in the New York Times, says, “There are scenes all across California that illustrate the power of the drought… People are watering trees with discarded dishwater, running the washing machine once a week, and letting their carefully tended beds of flowers and trees wither into patches of dusty dirt.”

California’s water woes illustrate the waterworks industry’s responsibilities and challenges faced in just one state. But these responsibilities and challenges, plus people’s overall reliance on the waterworks industry is a global challenge that is expected to become even more critical with time.

Common themes seem to be repeated in waterworks industry reports and news, including:

- Drought is expected to continue in California for some time into the future.

- The global population will keep growing, placing increasing demand on the world’s water supplies in the coming years and decades. In one industry report about the UK, alone, they predict “35% growth in water demand could be possible by 2050 due to population growth.”

- The aging water infrastructure in the U.S. and around the world will need to be refurbished or replaced in the very near future to keep things pumping and flowing and to continue to meet global water supply demands.

Reporting on the aging U.S. water infrastructure, an American Water white paper, “Challenges in the Water Industry: Infrastructure and its Role in Water Supply,” says, “Today, this massive water supply system, serving 240 million Americans, is in serious need of replacement, upgrading and maintenance if it is to continue to support a growing U.S. population.”

While the challenges may change as the population grows and technology advances, the waterworks industry will continue to be charged with the responsibility of finding water resources, treating the water so that it’s consumable, and keeping the water flowing to where it’s needed most. Centrifugal clutches play a role in keeping the water flowing and pumping in all types of waterworks facilities. Compressors, engines, pumps, and generators often include and rely on centrifugal clutches. Through our experience manufacturing centrifugal clutches for a wide variety of industries, including the waterworks industry, we’ve seen first-hand how critical it is to keep things pumping and flowing in the waterworks industry. At BLM Automatic Clutch, we’re ready to partner with and assist companies in the waterworks industry to help overcome whatever challenges flow our way.

Proper Hurricane Season Preparedness

As summer comes to an end and fall arrives, hurricane season comes along with it. While we can’t know what lies ahead, we do know that hurricanes of some sort are to be expected, and the best thing we can do is be prepared.

When Hurricane Sandy wreaked havoc along the northeast, devastating towns and cities, most people weren’t mentally or physically prepared for how bad it would be—countless people lost their homes, businesses, and more. Just recently, when typhoon Utor ripped through Hong Kong, everything, including their stock exchange, came to a close. And many people might remember the blackout that occurred almost exactly 10 years ago, affecting 55 million people throughout the northeast and Canada. Natural disasters and power losses can be catastrophic.

When these things occur and cities shut down, the ones that get through it best are often those that are best prepared. Learning from these disasters led many people to invest in good pumping systems, chippers, clutches, and other equipment. Standby diesel engines often provide the power when water treatment plants and the electric grid fail, and those engines rely on clutches.

Additionally, when hurricanes or typhoons hit and major flooding occurs, pumping systems properly remove the excess water. We have seen it countless times—municipalities calling us in the wake of a disaster, in need of pumps and clutches.

Furthermore, when strong winds cause falling trees (or even buildings), chippers are used for the cleanup, making the streets clear and safe. Rider trowels take care of the issues that arise from large concrete buildings, while plate tampers pack down the road surfaces and redo damaged asphalt. Accordingly, curbers fix the edging of sidewalks, making them safe for pedestrians following a big storm.

All of these are necessary to undo the damage done by these types of disasters. And while no one can truly predict what will come our way, being prepared can help you literally weather the storm.

Ready… Set… Go! Try Go-Karting for Corporate Team Building

Having fun is a big part of corporate culture today. Companies big and small, from Google and Microsoft to the accounting firm down the road, are incorporating “fun” into their business plans. Merging the “fun-factor” into a business’ daily operations isn’t a new trend: It’s been around for quite some time now, especially in corporate team building efforts around the world.

On his website, www.teambuilding123.com, team building expert David Greenberg lists the following advantages and results of corporate team building efforts:

- People getting to know each other better

- Improved communication and trust

- The breakdown of barriers and “silos” between departments

- The ability to recognize and capitalize on each other’s talents and contributions

- More creativity and innovative problem-solving

- The creation of strong, effective teams who know how to work together toward a common goal.

Team-building activities range from quiet canoe rides down tranquil rivers and streams, to more challenging and active adventures. Go-karting is one type of team building activity that is extremely popular across the country today. Satisfying “the need for speed,” go-karting has been proven to be very effective for team building efforts, as well.

Driving a go-kart at high speeds in a safe, controlled, indoor environment provides all the ingredients needed for fun, excitement and, most importantly, interaction among people. It’s a great way to build rapport between departments and between different levels of company employees. Racing brings people together, encourages collaboration, and breaks down departmental barriers.

From San Diego, to Denver, to New York, you’ll find indoor go-karting locations that feature corporate teambuilding events as part of their offerings. Many locations have quiet meeting rooms on site, in addition to their go-kart racetracks. Of course, safety is key, and the equipment used at commercial go-karting outlets is maintained to be responsive and to quickly accelerate for powerful results on the track. The go-karts you find at commercial establishments are heavy-duty and they’re manufactured with strong, dependable clutches built for the long haul. We know this because we manufacture fully machined centrifugal clutches for commercial go-karts, and, of course, they’re designed for serious performance and durability.

While the goal and mission of team building through go-karting is serious business, and the centrifugal clutches are commercial-grade and provide exceptional performance, the end results of go-karting for corporate teambuilding are always guaranteed fun!

Environmental factors that affect agriculture

Our planet is a well-timed and well-run ecosystem that relies on so many factors, plants, animals and insects to keep it humming in harmony. One of the areas that are out of tune has been the serious decline of the honeybee population in the United States. Recently, scientists at Purdue University identified one of the largest factors that are causing the disappearance of these bees.

Bees are necessary for the pollination of our fruits and vegetables. Without their work buzzing from tomato flower to blackberry blossom, we won’t get large crops of tomatoes, blackberries, water melons, apples, pears, and on and on.

The Purdue scientists found that the dead bees around the fields and hives over a two year period showed the presence of neonicotinoid insecticides. These are commonly used to coat corn and soybean seeds prior to planting. The researchers found that high concentrations of these insecticides were found in the waste talc that is exhausted from farm machinery during the spring planting. Christian Krupke an associate professor of entomology and co-author of the study in an interview said, “We know that these insecticides are highly toxic to bees; we found them in each sample of dead and dying bees.”

The seeds for most crops are coated with this insecticide to protect them after they are planted. All corn and half of all soybean seeds are treated in this manner. The coated seeds are sticky and because they clog up the vacuum systems that are used for planting, they are mixed with talc. This talc gets released into the local environment during the planting process. This contaminated talc is blown into the air and bees encounter the toxic substance when they land on anything that has a talc coating.

There are other methods of protecting crops that can eliminate or reduce this toxic talc that the bees are encountering. Spraying after the crops have been planted is one method, rather than coating the seeds. BLM is proud to have our clutches in various agricultural applications from sprayers, to wood chippers, to crop conveyors.

In fact, our distinctive blue clutches have always been quite green. Which we feel is a big way that we can help to contribute to a sustainable planet.

An electric motor with a centrifugal clutch starts under no load and does not engage and drive the load until it reaches near rated speed. Once it is up to speed, the motor will have more torque to start and accelerate the load. This then consumes less current than if a motor were to start under a full load.

The environmental benefits include:

- More improved power that runs efficiently

- Reduction in electrical power consumption

- Increased motor life, which provides continuous savings on energy consumption

Everything that we can do to make changes that protect and enhance our ecosystem is important. Whether it is the way that we protect our agricultural crops in order to protect the honeybees that are integral to their growth or by using clutches that are more energy efficient but still provide the power needed to get the job done.

800.268.4295

800.268.4295