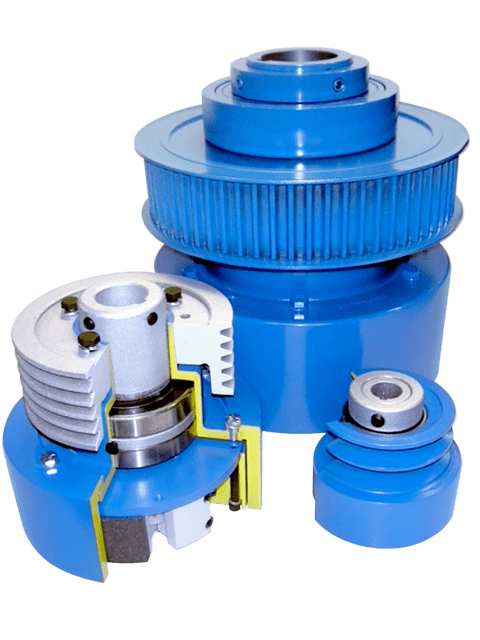

BLM designs and manufactures centrifugal clutches for a wide variety of small and large applications. They are integral machinery components in almost every industry, and there are numerous benefits to their usage. This critical component is ideal for starting power equipment safely and effectively.

How a centrifugal clutch operates

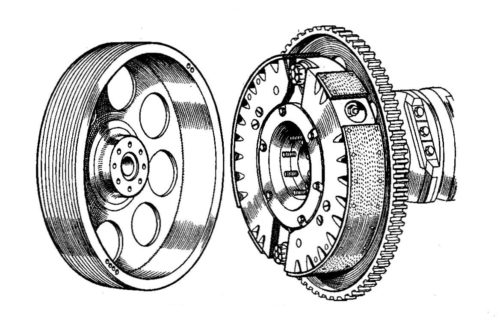

The primary purpose of a centrifugal clutch is to connect the power source (engine, motor, turbine, etc.) to the load that is accelerated. It uses centrifugal force to turn the driveshaft and acts as a transmission activated by the increasing rpm of the engine. It uses centrifugal force to turn the driveshaft and basically acts as a transmission that is activated by the increasing rpm of the engine. Sizing the clutch to the running requirements of the load, and not the horsepower capacity of the motor, allows the motor to develop maximum torque and offers the advantage of using a smaller motor and gear reducer.

The primary purpose of a centrifugal clutch is to connect the power source (engine, motor, turbine, etc.) to the load that is accelerated. It uses centrifugal force to turn the driveshaft and acts as a transmission activated by the increasing rpm of the engine. It uses centrifugal force to turn the driveshaft and basically acts as a transmission that is activated by the increasing rpm of the engine. Sizing the clutch to the running requirements of the load, and not the horsepower capacity of the motor, allows the motor to develop maximum torque and offers the advantage of using a smaller motor and gear reducer.

Utilizing a centrifugal clutch allows maximum torque with minimum current draw. This is the most efficient condition for accelerating the load as the clutch does the slipping and heat dissipation, preventing the motor from absorbing the heat and then becoming damaged by it. Clutches can be adjusted for capacity by varying the weight of the internal operating mechanism enabling a wide range within each clutch size.

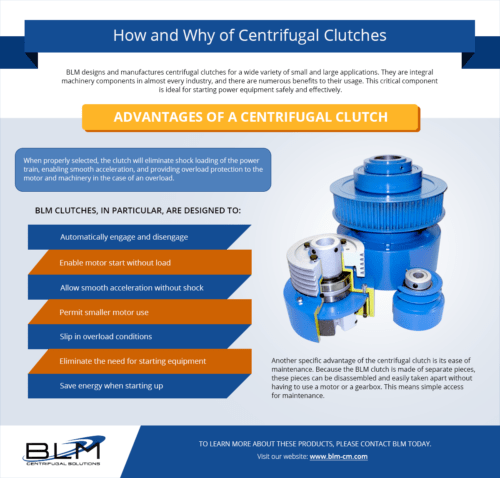

Advantages of a centrifugal clutch

When properly selected, the clutch will eliminate shock loading of the power train, enabling smooth acceleration, and providing overload protection to the motor and machinery in the case of an overload.

When properly selected, the clutch will eliminate shock loading of the power train, enabling smooth acceleration, and providing overload protection to the motor and machinery in the case of an overload.

BLM clutches, in particular, are designed to:

- Automatically engage and disengage

- Enable motor start without load

- Allow smooth acceleration without shock

- Permit smaller motor use

- Slip in overload conditions

- Eliminate the need for starting equipment

- Save energy when starting up

Another specific advantage of the centrifugal clutch is its ease of maintenance. Because the BLM clutch is made of separate pieces, these pieces can be disassembled and easily taken apart without having to use a motor or a gearbox. This means simple access for maintenance.

View Our Catalog of CAD Drawings

Common uses and applications

Most people are familiar with the clutches used in personal vehicles such as cars and motorcycles, but in reality, you might be surprised to find just how many applications there are for centrifugal clutches in other areas. Centrifugal clutches are widely used in machinery throughout industrial applications, including mining, manufacturing, and the military, to protect motors from damaging conditions and to keep machinery running at optimal levels.

The mining industry relies on heavy-duty machines with reliable and durable components. Coal crushers are one example. Put simply; a coal crusher is a machine used for crushing rock and other bulk materials for further processing. They reduce hard materials such as ore, coal, and stone into smaller particles that are more convenient to use. These machines work by feeding the material between two large rollers that turn together while applying great force. They rely on a clutch, which connects the two rolling components so that they can spin together at the same speed.

The mining industry relies on heavy-duty machines with reliable and durable components. Coal crushers are one example. Put simply; a coal crusher is a machine used for crushing rock and other bulk materials for further processing. They reduce hard materials such as ore, coal, and stone into smaller particles that are more convenient to use. These machines work by feeding the material between two large rollers that turn together while applying great force. They rely on a clutch, which connects the two rolling components so that they can spin together at the same speed.

In the chemical industry, clutches are employed in mixers. Mixers come in a number of different shapes and sizes but mostly work according to the same principle. They use a motor to drive the shaft and blade rapidly, in a circular motion. In this case, the clutch serves to transmit motion from the motor to the mixer shaft, which then spins the blades. A special consideration when manufacturing clutches for the chemical industry is their ability to withstand heavy loads and demanding tasks.

Clutches are also widely employed in the military industry. In military aircraft, for example, clutches are found in autopilot systems, fuel control, and air cabin control systems, among many others. These clutches must be able to endure harsh environmental conditions without sacrificing the quality of performance. Some of these conditions include humidity, heat, and vibrations. This type of application often calls for high-performance friction materials.

Clutches are also widely employed in the military industry. In military aircraft, for example, clutches are found in autopilot systems, fuel control, and air cabin control systems, among many others. These clutches must be able to endure harsh environmental conditions without sacrificing the quality of performance. Some of these conditions include humidity, heat, and vibrations. This type of application often calls for high-performance friction materials.

Over the past 80 years, at BLM Automatic Clutch, we’ve manufactured a countless number of friction clutches for several types of applications. We work with customers in all manufacturing industries, and our clutches come in all kinds of combinations: coupling, flywheel, universal shaft, pulley, and soft start combinations. Our experienced engineering, design, and manufacturing team can provide the correct clutch configuration to meet all types of requirements.

BLM clutches can be used to solve or eliminate common equipment problems associated with some of the following conditions:

- Cuts the duration of high amperage draw when motor is starting to less than one second.

- Overheating motors when starting is prevented by providing the equivalent of a no-load start.

- Using oversized motors for starting, which can cause shock loads and bad power factor, are not necessary since the clutch enables using a motor with a capacity closer to the running load.

- No need to use reduced voltage starters since simple across-the-line starters can be used with a clutch.

- Starting shock, a condition that causes damage to moving parts and is a major cause of equipment maintenance, is not an issue with a BLM clutch since soft starts increase the life of components such as belts and gears.

- Fragile materials (wires, thread, paper) are often subject to breakage as the result of stating shock; the gentile, low torque starting of a clutch eliminates breakage and downtime.

- Difficulty of starting heavy loads is problematic but a clutch selected for cushioned, high torque starts can easily handle heavy loads.

- Motor burnout because of overloads won’t occur with a clutch that slips before the motor is damaged.

- High overload torque capacity of the motor causes overload damage. A properly selected clutch slips under the overload at a torque level lower than the motor capacity.

- Sudden overloads that cause damage due to the flywheel effect of the motor rotor are eliminated because the clutch will slip when a jam-up occurs to protect against damage to the motor.

BLM Solutions

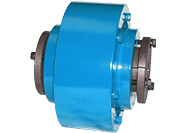

BLM’s clutch mechanism offers a distinct competitive advantage. In competitors’ clutches, the majority are made as one solid unit, making it extremely difficult to do anything without taking the clutch apart entirely—not a quick, easy fix.

However, our mechanism is in a drive body attached to a flange that can easily be dropped out, allowing the user to change the clutch out in a very short period of time. As anyone knows, saving time and money when it comes to maintenance are two of the biggest factors in remaining competitive, efficient, and successful.

However, our mechanism is in a drive body attached to a flange that can easily be dropped out, allowing the user to change the clutch out in a very short period of time. As anyone knows, saving time and money when it comes to maintenance are two of the biggest factors in remaining competitive, efficient, and successful.

Our custom centrifugal clutches are backed by over 80 years of experience. In this time, we’ve perfected the design of the clutch, knowing how to make them high quality, long-lasting, and extremely easy to use and maintain.

BLM’s centrifugal clutches are available in a wide range of sizes with custom solutions available for any application. We have the experience and expertise to engineer custom centrifugal clutches that will solve even the most challenging equipment problems. To learn more about these products, please contact BLM today.

800.268.4295

800.268.4295