At BLM Automatic Clutch, our industry-leading centrifugal clutches play a critical role in the public works and utilities industries. They are designed for minimal downtime and maximum productivity without significant maintenance requirements.

Additionally, they are suitable for use with a variety of equipment, including pumps, chippers, and sweepers.

Why Are Centrifugal Clutches Ideal for Public Works and Utility Applications?

Centrifugal clutches connect power sources, such as an engine, motor, or turbine, to loads that need acceleration. When activated, the engine rotates the clutch, which, in turn, uses the centrifugal force generated to turn the driveshaft.

These critical components are available in several design variations to suit different applications. Ideally, when fitted into a system, the selected clutch should enable smooth acceleration, eliminate shock loading of the powertrain, and protect the power source and connected equipment from power overload.

Within the public works and utilities industries, all of the above are essential to achieving and maintaining safe and reliable operation. Additionally, industry professionals look for the most cost-effective component for their applications. For these reasons, they often turn to centrifugal clutches, which offer:

- Low investment cost. Centrifugal clutches have a lower initial cost than other types of clutches, in part, because they have fewer parts and require no battery or additional components.

- Minimal maintenance and servicing requirements. As centrifugal clutches have fewer parts, they also need less time for component maintenance and repair operations.

- Smooth operation. Centrifugal clutches are designed to provide smooth, shockless acceleration and progressive engagement with the load, which is safer and minimizes the strain and burden placed on the equipment.

In addition to offering the above advantages, BLM’s centrifugal clutches deliver the following:

- Automatic engagement and disengagement

- Motor startup without a connected load

- Smooth acceleration without shock

- Suitability for smaller motors

- Slip in overload conditions

- No need for starting equipment

- Low energy utilization on startup

Read more: Advantages of Centrifugal Clutches

Public Works and Utility Applications of Centrifugal Clutches

From wood chippers to water and wastewater treatment systems, centrifugal clutches are employed in a variety of public works equipment and utility operations, including:

- Street sweepers: keep streets clean, clear debris from construction sites, and prevent unwanted materials from flowing in the sewer system

- Wood chippers: clear branches and tree debris generated by from natural disasters

- Pumping systems: facilitate the operation of stormwater management systems

- Street curbers: construct small- to medium-sized curbs made from asphalt or concrete

- Power trowling machines: spread out poured concrete to achieve a more finished look

- Air compressors: serve as a power source for pneumatic tools and a critical component in some HVAC systems

- Water/wastewater treatment systems: manage the processing and cleaning of water and wastewater

Public Works Case Study: Pulley-Style Clutch System

BLM Automatic Clutch was contracted by an OEM customer in the public works industry to manufacture a custom clutch.

BLM was required to meet exacting standards while preserving customer price criteria, as they were stepping in to produce the part after a previous supplier could no longer maintain an acceptable price point.

A flywheel mounted clutch and pulley system was required for an industrial sweeper application, with a mandatory 5 grove, 5V, 10″ pulley. This was not a problem for BLM, who was able to convert drawings of an existing pulley style clutch system into the part meeting the customer’s parameters.

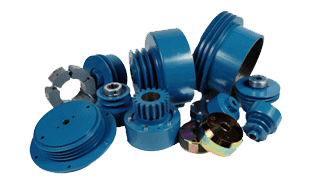

Composed of steel and precision machined using state-of-the-art CNC lathes and milling equipment, the unit was assembled and finished with a coating of blue paint. The finished 8″ clutch met the space, size, and configuration requirements in the 150 HP sweeper with an idle RPM of 800 and operating RPM of 3000. 30 units were constructed after a turnaround time of 8 weeks and shipped to the customer in Japan. All products were fully dimensionally inspected for quality and accuracy. BLM is fully prepared to replace customer components with more cost effective solutions.

Public Works Case Study Specifications

Project Scope

The OEM required a flywheel mounted clutch and a pulley. The pulley needed to be a 5 groove, 5V with a 10″ diameter. The previous OEM was unable to continue supplying at an acceptable price point. BLM was able to retrofit to meet space size and configuration requirements at the right price point

Product Application

Industrial Sweeper 150 HP/3000 RPM/800 IDLE

Product Description

6″ clutch B66SKM with QD bushing

Clutch Fabrication Capabilities Applied/Processess

Primary:

- Material Sourcing

- CNC Turning

- CNC Milling

Secondary::

- Assembly

- Painting

Design

Modification of appropriate drawing from portfolio of 4000+ drawings

Equipment Used to Manufacture Part

CNC Lathes, CNC Mills, Various Machine Shop Equipment

Tightest Tolerances

± 0.003″

Material Used

Steel

Material Finish

Paint

Color: Blue

In process testing/inspection performed

Dimensional Inspection

Industry for Use

Public Works

Volume

30 Units

Delivery/Turnaround Time

8 Weeks

Delivery Location

Japan

Standards Met

Customer Specifications, 2D Drawing

Product Name

Centrifugal Clutch

City Waterworks Case Study

BLM Automatic Clutch was contracted by an OEM customer in the City Waterworks industry to manufacture a custom clutch.

Customer needed an alternate solution to the originally specified clutch. The OEM clutch required alignment to be maintained between the driven and drive side shafts. In use the clutch continually failed because of the inability to maintain alignment.

BLM was able to offer a solution using a gear coupling which permits for misalignment and by modifying a design to fit the customer’s space requirement.

For more information about this custom centrifugal clutch project, or the other custom clutch capabilities for demanding industrial applications, please see the table below.

Waterworks Case Study Specifications

Product Application

Pump 60 HP/1800 RPM/800 IDLE

Product Description

8″ clutch GMG 80M3

Clutch Fabrication Capabilities Applied/Processes

Primary:

- Material Sourcing

- CNC Turning

- CNC Milling

Secondary::

- Assembly

- Painting

Design

Modification of appropriate drawing from portfolio of 4000+ drawings

Equipment Used to Manufacture Part

CNC Lathes, CNC Mills, Various Machine Shop Equipment

Tightest Tolerances

± 0.003″

Material Used

Gray Iron

Material Finish

Paint

Color: Blue

In process testing/inspection performed

Dimensional Inspection

Industry for Use

City Waterworks

Volume

30 Units

Delivery/Turnaround Time

8 Weeks

Delivery Location

USA

Standards Met

Customer Specifications, 2D Drawing

Product Name

Centrifugal Clutch

Quality Centrifugal Clutch Solutions from BLM Automatic Clutch

The BLM team has extensive experience in the design and manufacture of centrifugal clutches. Our custom clutches are fully machined to meet tight tolerances and customer specifications, including in regard to engine horsepower and RPM.

Whether you require a prototype, single-use part, or OEM product, we can help bring your idea to fruition. For more information on our product availability, capabilities, and pricing, contact us today.

800.268.4295

800.268.4295