A customer in the mining industry needed an inline clutch to work within a limited space coal crusher application.

BLM was selected to develop a high-performance replacement for an OEM product that was exhibiting a high failure rate. Adapting a drawing from their portfolio of over 4000 drawings, the unit was constructed using gray iron and BLM’s advanced machining capabilities. This included engine lathes, Milling machines, and other machine shop tools and processes. The unit was turned and milled holding a tight ± 0.003″ tolerance.

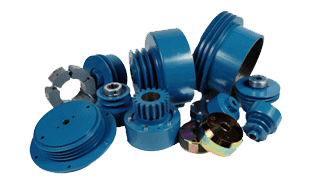

The part was assembled and finished with a blue paint coating. Full dimensional inspections were carried out during production to ensure quality and integrity.

The resulting 18″ clutch featured a bushing on the driven side and bored to suit on the drive side, as specified for the 125 HP, 700 operating RPM application. Turnaround time for the centrifugal clutch was 12 weeks, and 2 were produced for shipment to the customer. BLM is prepared to work with customers to provide customized solutions to their demanding applications, with focus on high quality and cost effectiveness.

For more information about this centrifugal clutch fabrication, or the other custom solutions available, please see the table below or contact BLM directly.

Project Scope

Project Scope

The customer required an inline clutch with space limitations. The previously installed clutch failed after 2 years use due to incorrect specification. BLM initially worked with the OEM but did not win the original order because our custom designed clutch took longer to produce than the off-the-shelf solution the OEM originally settled on. When this clutch failed the OEM contacted BLM to resolve the problem

Product Application

Coal Crusher 125 HP/700 RPM

Product Description

18″ clutch A180MH with bushings on the driven side and bored to suit on the drive side

Clutch Fabrication Capabilities Applied/Processes

Primary:

- Material Sourcing

- Milling Machine

- Lathe Machined

Secondary::

- Assembly

- Plating

Design

Modification of appropriate drawing from portfolio of 4000+ drawings

Equipment Used to Manufacture Part

Milling Machines, Various Machine Shop Equipment

Tightest Tolerances

± 0.003″

Material Used

Gray Iron

Material Used

Gray Iron

Material Finish

Paint

Color: Blue

In process testing/inspection performed

Dimensional Inspection

Industry for Use

Mining

Volume

2

Delivery/Turnaround Time

12 Weeks

Delivery Location

USA

Standards Met

Customer Specifications, 2D Drawing

Product Name

Centrifugal Clutch

800.268.4295

800.268.4295