Should I Use a Centrifugal Clutch or a Torque Converter?

Leave a CommentIn power transmission applications, power can be transmitted from the driving component to the driven component by a variety of mechanical devices. Two of the most common devices utilized for this purpose are clutches (e.g., centrifugal clutches) and fluid couplings (e.g., torque converters). Below, we highlight how each of the devices works and what applications they are used in to help you understand which is best suited for your power transmission application.

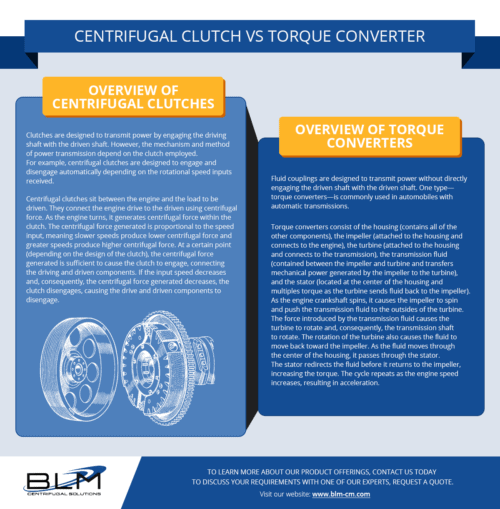

Centrifugal Clutch vs. Torque Converter

Overview of Centrifugal Clutches

Clutches are designed to transmit power by engaging the driving shaft with the driven shaft. However, the mechanism and method of power transmission depend on the clutch employed. For example, centrifugal clutches are designed to engage and disengage automatically depending on the rotational speed inputs received.

Centrifugal clutches sit between the engine and the load to be driven. They connect the engine drive to the driven using centrifugal force. As the engine turns, it generates centrifugal force within the clutch. The centrifugal force generated is proportional to the speed input, meaning slower speeds produce lower centrifugal force and greater speeds produce higher centrifugal force. At a certain point (depending on the design of the clutch), the centrifugal force generated is sufficient to cause the clutch to engage, connecting the driving and driven components. If the input speed decreases and, consequently, the centrifugal force generated decreases, the clutch disengages, resulting in the drive and driven components to separate.

Overview of Torque Converters

Fluid couplings are designed to transmit power without directly engaging the driven shaft with the driven shaft. One type—torque converters—is commonly used in automobiles with automatic transmissions.

Torque converters consist of the housing (contains all of the other components), the impeller (attached to the housing and connects to the engine), the turbine (attached to the housing and connects to the transmission), the transmission fluid (contained between the impeller and turbine and transfers mechanical power generated by the impeller to the turbine), and the stator (located at the center of the housing and multiples torque as the turbine sends fluid back to the impeller). As the engine crankshaft spins, it causes the impeller to spin and push the transmission fluid to the outsides of the turbine. The force introduced by the transmission fluid causes the turbine to rotate and, consequently, the transmission shaft to rotate. The rotation of the turbine also causes the fluid to move back toward the impeller. As the fluid moves through the center of the housing, it passes through the stator. The stator redirects the fluid before it returns to the impeller, increasing the torque. The cycle repeats as the engine speed increases, resulting in acceleration.

Differences Between Centrifugal Clutches and Torque Converters

The main differences between centrifugal clutches and torque converters are:

- Centrifugal clutches connect the engine to the transmission, while torque converters allow the engine and transmission to run independently from one another.

- Centrifugal clutches are suitable for power transmission applications involving high speeds, while torque converters are suitable for power transmission applications involving heavy loads.

View Our Catalog of CAD Drawings

Applications for Centrifugal Clutches and Torque Converters

Both centrifugal clutches and torque converters are used in power transmission applications. However, as they employ different power transmission mechanisms and methods, they are suitable for different use cases.

Typical applications for centrifugal clutches include:

- Chippers

- Saw mills

Typical applications for torque converters include:

- Conveyor belts

- Drill rigs

- Forklifts

Centrifugal Clutches From BLM

Both centrifugal clutches and torque converters play a critical role in power transmission operations across a wide range of industries. Compared to other types of clutches, centrifugal clutches offer numerous advantages, including simpler operation, lower maintenance costs, smoother acceleration, and better engagement speed control.

Looking for quality centrifugal clutches for your power transmission system? BLM Automatic Clutch has you covered. We design and manufacture custom centrifugal clutches with input speed capacities ranging from fractional to 3,000 hp. To learn more about our product offerings, contact us today. To discuss your requirements with one of our experts, request a quote.

800.268.4295

800.268.4295