Heavy-Duty Centrifugal Clutches: A BLM Case History

BLM Automatic Clutch has been involved in some of the world’s most significant marine engineering undertakings. Our legacy is built on advanced engineering with practical application to global challenges, and our integral contribution to the St. Lawrence Seaway is a case in point. BLM’s advanced heavy-duty centrifugal clutches contributed to the ambitious waterway’s success by enabling the hydraulic dredgers to safely and efficiently remove massive volumes of earth around the clock while protecting equipment and operators.

In the 1950s, large transatlantic ships had trouble sailing up the St. Lawrence River to get to the Great Lakes from the Atlantic. To resolve this, a joint venture between America and Canada built the St. Lawrence Seaway—a system of locks, canals, and channels that would enable ocean-going vessels to travel as far inland as Duluth, Minnesota, on the western side of Lake Superior. The St. Lawrence Seaway and River are a vital economic and geographic feature of the Great Lakes region, enabling deep-draft ocean vessels to bypass New England ports and reach the American Midwest and the most populous Canadian cities directly.

This marvel of 20th-century engineering was achieved through the cooperation of many organizations, including BLM. We designed and manufactured engine clutches strong enough to withstand the high forces of deep-river dredging.

What Is a Heavy-Duty Centrifugal Clutch?

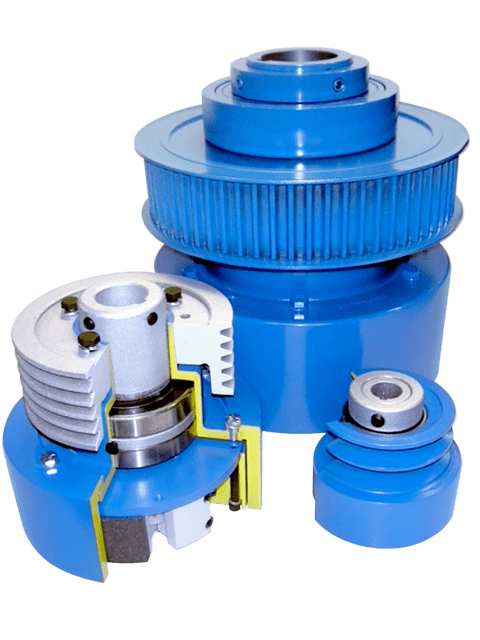

The majority of standard centrifugal clutch designs are only appropriate for motors with fractional to 50 HP. BLM’s heavy-duty centrifugal clutches are capable of handling 800 HP engines and are central to powering large-scale projects like the St. Lawrence Seaway.

BLM is still a world-leading provider of centrifugal clutches for high-torque applications. Our advanced clutch technology ensures efficient power transmission while minimizing load forces. The result is longer-lasting equipment and overload protection that keeps operators safe and lets them turn hydraulic pumps off without slowing the engine down. This factor proved crucial for the continual operation of the hydraulic pumps involved in the St. Lawrence Seaway.

Engineering the St. Lawrence Seaway

The St. Lawrence Seaway is still considered one of the 20th century’s most important engineering feats. Construction of the seaway started a new era of marine transportation and engineering. The 189-mile seaway was built by a 22,000-strong workforce that moved 210 million cubic yards of earth and laid over 6 million cubic yards of concrete. BLM’s heavy-duty centrifugal clutches powered the continual hydraulic dredging equipment responsible for removing this high volume of earth and rock.

Our heavy-duty clutch couplings fit between the hydraulic dredgers’ diesel engines and pumps, enabling continuous, smooth operation so that the dredges would not break down. Here’s how our clutch benefited this project:

- It protected the engines and pump rotors by automatically slipping if excessively large rocks entered the pump casing.

- The clutch coupled the pump to the engine with a self-aligning spherical roller pilot bearing to maintain alignment.

- Idle speed could be automatically set to 200 RPM, which allowed operators to discontinue pumping without shutting the engine down. This was a crucial factor in preventing excessive wear to motors due to repeatedly restarting the engine.

Custom Centrifugal Clutches by BLM

Today, the St. Lawrence Seaway is still a vital waterway for Canadian and American global trade, as it facilitates the transportation of 40-50 million tons of cargo every year. For almost a century, BLM has been working closely with customers to develop prototypes to ensure they have the product they need before committing to large-scale orders. Our custom centrifugal clutches keep their employees and equipment safe even under extreme conditions.

We also design and manufacture one-off industrial centrifugal clutches to replace obsolete OEM parts. These specialized centrifugal clutches deliver exceptional functionality to their specific application. Contact us to learn more about our custom clutches, capabilities, or other case studies. To get started on your project, request a quote today.

800.268.4295

800.268.4295

The primary purpose of a

The primary purpose of a

The mining industry relies on heavy-duty machines with reliable and durable components. Coal crushers are one example. Put simply; a coal crusher is a machine used for crushing rock and other bulk materials for further processing. They reduce hard materials such as ore, coal, and stone into smaller particles that are more convenient to use. These machines work by feeding the material between two large rollers that turn together while applying great force. They rely on a clutch, which connects the two rolling components so that they can spin together at the same speed.

The mining industry relies on heavy-duty machines with reliable and durable components. Coal crushers are one example. Put simply; a coal crusher is a machine used for crushing rock and other bulk materials for further processing. They reduce hard materials such as ore, coal, and stone into smaller particles that are more convenient to use. These machines work by feeding the material between two large rollers that turn together while applying great force. They rely on a clutch, which connects the two rolling components so that they can spin together at the same speed. Clutches are also widely employed in the military industry. In military aircraft, for example, clutches are found in autopilot systems, fuel control, and air cabin control systems, among many others. These clutches must be able to endure harsh environmental conditions without sacrificing the quality of performance. Some of these conditions include humidity, heat, and vibrations. This type of application often calls for high-performance friction materials.

Clutches are also widely employed in the military industry. In military aircraft, for example, clutches are found in autopilot systems, fuel control, and air cabin control systems, among many others. These clutches must be able to endure harsh environmental conditions without sacrificing the quality of performance. Some of these conditions include humidity, heat, and vibrations. This type of application often calls for high-performance friction materials. However, our mechanism is in a drive body attached to a flange that can easily be dropped out, allowing the user to change the clutch out in a very short period of time. As anyone knows, saving time and money when it comes to maintenance are two of the biggest factors in remaining competitive, efficient, and successful.

However, our mechanism is in a drive body attached to a flange that can easily be dropped out, allowing the user to change the clutch out in a very short period of time. As anyone knows, saving time and money when it comes to maintenance are two of the biggest factors in remaining competitive, efficient, and successful.